Complete System

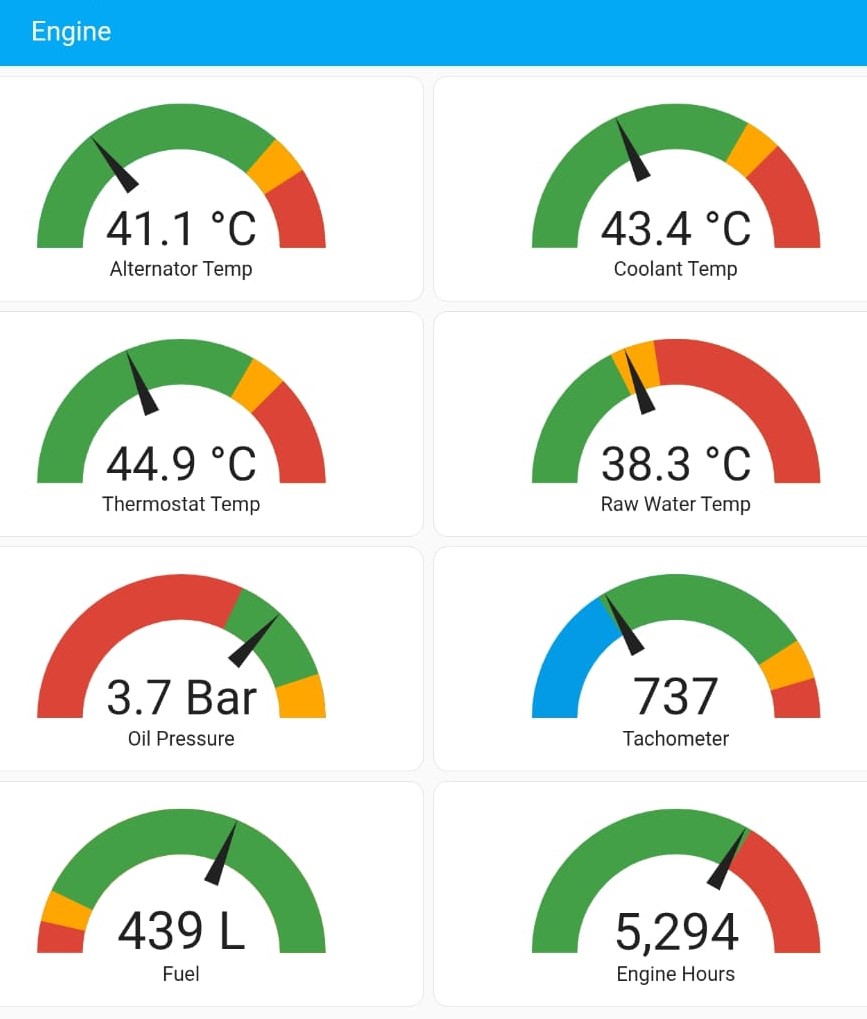

Build a complete engine-monitoring dashboard with 8 gauges: 4× Temperature (DS18B20) + 1× Tachometer (RPM) + 1× Oil Pressure + 1× Fuel Tank Level + 1× Engine Hours. All sensors feed a single ESP32 running ESPHome, visualised in Home Assistant.

- 4× Temp gauges

- 1× Tachometer

- 1× Oil pressure

- 1× Tank level

- 1× Engine hours

As featured in PBO:

How I installed a smart engine monitoring system on my sailboat

.

🧭 What You’ll Build

- One ESP32 “remote hub” that reads multiple sensors (1-Wire, I²C, pulse) in the engine bay

- 8 total gauges: 4× temperature (raw-water elbow, alternator, coolant area, thermostat), 1× tachometer (RPM), 1× oil pressure, 1× fuel tank level, 1× engine hours

- Color-coded needle gauges, history trends, and alert automations (siren/horn/notifications)

- A scalable pattern to add more sensors over time (additional DS18B20s / INA219s)

🧩 System Architecture

- Sensors → ESP32: DS18B20 (1-Wire), INA219 (I²C), alternator tacho via optocoupler (pulse)

- Firmware: ESPHome on the ESP32 (OTA updates)

- Backend: Home Assistant on Raspberry Pi (entities, templates, dashboards, automations)

- Power: 12 V → 5 V DC-DC buck to ESP32; 3.3 V rails for sensors

💡 Practical wiring pattern

- Use a screw-terminal breakout for the ESP32 to make engine-bay wiring robust

- Route all DS18B20s to a single data pin with one 4.7 kΩ pull-up

- Put INA219s on SDA

GPIO21/ SCLGPIO22; up to 8 per ESP32 with unique addresses - Feed alternator W/stator/tacho to a 24 V optocoupler module → ESP32

GPIO25(pulse counter)

🧰 Consolidated Parts & Tools

- ESP32 dev board (30-/38-pin) + screw-terminal breakout/enclosure

- DS18B20 waterproof probes (1–5+ as needed) + 4.7 kΩ resistor (single pull-up for the bus)

- INA219 modules (for oil sender & fuel sender; supports more tanks/senders)

- Optocoupler input module (24 V recommended) for alternator tacho

- Wiring: Dupont leads, double spade adapters, cable ties, strain relief

- Power: 12 V → 5 V DC-DC buck (boat install) or USB (bench)

- Optional alert devices: siren/horn, lights; optional relay for alternator cooling strategy

🚀 Build at a Glance

- Provision an ESP32 in ESPHome; confirm OTA and logs work.

- Add modules one by one:

- DS18B20 temperature bus on

GPIO25with 4.7 kΩ pull-up → discover addresses (aim for 4 probes → 4 gauges) - INA219 on I²C (

SDA 21,SCL 22) → read sender voltage (oil & fuel) - Optocoupler from alternator W/stator/tacho → ESP32

GPIO25pulse counter

- DS18B20 temperature bus on

- Use the YAML snippets for each module (links below).

- Calibrate (voltage→pressure, voltage→% full, pulses→RPM) using your engine’s values.

- Create HA dashboards (needle gauges, severity bands) and add alert automations.

🧱 Modules (Start Here → Then Open Each Full Guide)

Engine Temperature (DS18B20)

- 4× temperature gauges (raw-water elbow, alternator, coolant area, thermostat)

- 1-Wire bus on

GPIO25, 4.7 kΩ pull-up - HA gauges + alternator > 100 °C alert

Oil Pressure (INA219)

- 1× oil-pressure gauge (volts → bar, two-point calibration)

- Tap sender “Gauge” terminal →

INA219 VIN+ - I²C:

SDA 21,SCL 22

Digital Tachometer (Optocoupler)

- 1× tachometer gauge (pulse counter → RPM)

- Alternator W/stator/tacho → optocoupler → ESP32

GPIO25 - Includes:

engine_hours(counter); optionalengine_active

Fuel Tank Level (INA219)

- 1× tank-level gauge (volts → % full)

- Sender “Gauge” terminal →

INA219 VIN+ - ESPHome exposes Tank Sender Voltage; HA template maps volts → %

📎 Series links (quick list)

📟 Dashboards & Automations

Gauges

- Total: 8 gauges → 4× temperature + 1× oil pressure + 1× RPM + 1× tank level + 1× engine hours

- Temperature gauges (needle) with severity: e.g., yellow 30 °C, red 42 °C at the raw-water elbow

- Oil pressure 0–5 bar (needle), green ≈ 3, yellow 4, red 0

- RPM 0–2400 with idle/amber/red bands

- Fuel level 0–100 % with low-fuel alert

- Engine hours counter (display card)

Automations

- Alternator > 100 °C → siren; optional relay to reduce field current

- Low oil pressure → horn/notification (gate by

engine_active) - Overspeed (RPM > threshold) → alert

- Low fuel (%) → notify before departure

History & Insight

- Compare last week’s engine temps to learn “normal” operating ranges

- Track oil pressure vs. RPM to spot wear or viscosity issues

- Correlate fuel usage with typical cruise RPM

🛠️ FAQs & Troubleshooting

DS18B20 shows as “unknown”

- Copy the discovered address from logs and replace the placeholder in YAML; check the 4.7 kΩ pull-up and bus wiring

INA219 reads 0.0 V

- Confirm I²C pins (

SDA 21,SCL 22) and that VIN+ is on the sender’s “Gauge” terminal

RPM unstable

- Verify alternator W/stator tap, optocoupler polarity, grounds; add another calibration point; keep wires short

📰 Featured by PBO

Read the Practical Boat Owner article covering this end-to-end project:

Then return here and follow the modules above to build your own system.

⚠️ Disclaimer

The information provided is for educational and informational purposes only. Perform all installations safely and correctly; consult a licensed professional for boat electrical work. Use at your own risk.

Tagged alternator tachometer, automations, boating diy, dashboards, digital tachometer, ds18b20, engine monitoring, engine temperature, esp32, esphome, fuel tank gauge, home assistant, i2c, ina219, marine electronics, marine iot, NMEA 2000, oil pressure monitoring, one-wire, open plotter, optocoupler, pbo, practical boat owner, pulse counter, raspberry pi, sailboat, signalk, smart boat, yacht